* 6-axis (Feed,Cut,Pitch,Torsion & initial tension) equipped as standard

* Torsion attachment and Cut axis are independent for easy set-up and high speed production

Assist tool can bo fit at apposite to cutting tool, and work range is broadened.

* Torsion axis of crank mechanism gives more preciseness, and expansion of clearance around arbor

portion, initial tension axis is placed inside the plate and also modified to straight movement that

enable to keep initial tension even if point is moved up-and-down

* General shaped spring parts such as cylindrical coil spring and conical spring can be formed with

the pattern program entering dimensional data. By changing factor, conical spring can be changed in

100-step, i.e fine adjustment can be done to get variety of shape like staight, bowl, triangle...

then, desired load can be achieved easily.

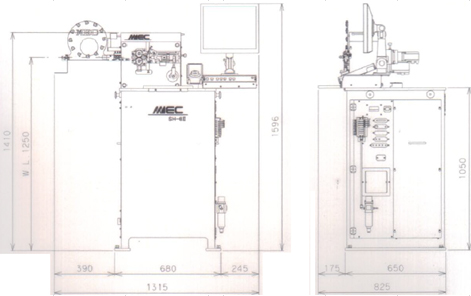

* Program screen shows all axes all time, and program flow, each axis operation, input/output, jump

and such can be seen with horizontal scroll.

* Varieties of gauging system (contact type, capacitance gage, and image sensor) are acailable.

Auto correction and multi-functional production management screen and such give easy production control.

Motor Sensor System (Standard spec.)

Applying functions of touch sensor and sercomotor positioning for cut-axis and pitch-axis enable to measure in 1/1000mm resolution to display graph, control amendment and so on.